For FEDAR digital printing machines(sublimation printer), the premise of high production capacity is to ensure that everything is normal. It is absolutely impossible to know how to use it without knowing how to maintain it. If you are in the same situation in front of the screen, you must be serious. Take notes!

Grating: Observe whether there is dust and stains on the grating. If you need to clean it, it is recommended to wipe it with a white cloth dipped in alcohol. The cleanliness and position changes of the grating will affect the movement of the trolley and the printing effect.

Filter: Regularly check whether the filter is clogged, clean and replace it in time.

Ink stack cap: keep it clean at all times, because the ink stack cap is an accessory that directly contacts the print head.

Scraper: The ink stack cleaning unit is kept clean, and the scraper is kept clean and undamaged to avoid affecting the ink scraping effect.

Ink cartridges and ink barrels: Clean the ink cartridges and waste ink barrels regularly. After long-term use, the ink remaining at the bottom of the ink cartridges and waste ink barrels may agglomerate, resulting in poor ink flow. It is necessary to clean the ink cartridges and waste ink barrels regularly.

Voltage regulator: It is recommended that each machine be equipped with a voltage regulator (only for printers, except for drying), not less than 3000W.

Ink: Ensure sufficient ink in the ink cartridge to avoid nozzle emptying, causing damage and blockage of the nozzle.

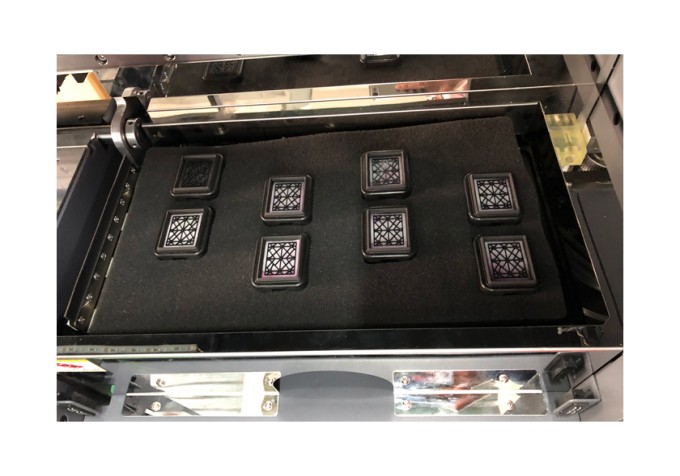

Printing platform: Keep the printing platform free of foreign objects to avoid scratches and damage to the nozzle.

Nozzle: Regularly check whether there is any accumulation of debris on the mirror surface of the nozzle and clean it up. You can move the trolley to the cleaning position, and use a cotton swab dipped in cleaning solution to clean the ink residue around the nozzle, so as not to affect the cleaning effect.

Ink sac: If the machine is used for a long time, check whether the ink sac is loose.

Transmission part: Grease is applied to the transmission part, and lubricating grease is regularly added to the meshing position of the gears, such as: the air shaft gear for retracting and unwinding materials, the guide rail slider, and the ink stack lifting mechanism. (It is recommended to add proper amount of grease to the long belt of the horizontal trolley motor, which can effectively reduce noise.)

Circuit inspection: Check whether the power cord and socket are aging.

Dryer: Regularly check whether the power supply of the dryer is aging and whether the internal lamp tube is damaged.

Air pump: Check whether the air pressure of the air pump is normal.

Working environment requirements: There is no dust in the room, so as to avoid the influence of dust on the layers of printing materials and ink consumables.

Environmental requirements:

1. The room should be dust-proof, and it cannot be placed in an environment prone to smoke and dust, and the ground should be kept clean.

2. Try to maintain a constant temperature and humidity environment. Generally, the temperature is 18°C-30°C and the humidity is 35%-65%.

3. No objects, especially liquids, can be placed on the surface of the machine.

4. The position of the machine should be flat, and it must be flat when loading materials, otherwise the long printing screen will be deviated.

5. There should be no commonly used household appliances near the machine, and keep away from large magnetic fields and electric fields.

FEDAR dye sublimation digital printing machine has outstanding performance in the production of cycling clothing. It has an unparalleled advantage in terms of speed, which meets the needs of current fast fashion!

FEDAR sublimation printer company has absorbed and condensed a group of high-quality professional technicians and enterprising young management groups, formed a strong technical team and increasingly rigorous management system,providing customers with high-quality printing machines and services,and has established a good brand image and reputation in industry.