Here are some key points to get you started on your

dye sublimation printer printing journey:

1. Understand the basics of dye sublimation printing, including the process, equipment, and materials.

2. Research and identify your target market to ensure there is a demand for your dye sublimation products.

3. Invest in quality dye sublimation equipment and supplies to deliver quality products to your customers.

4. Develop a strong business plan that outlines your goals, strategies and financial projections.

5. Create a well-designed website and establish a strong online presence to attract customers from around the world.

6. Experiment with different dye sublimation printing techniques and designs to offer unique and personalized products.

7. Establish strong relationships with suppliers and manufacturers to

to ensure a steady supply of materials at competitive prices.

8. Implement effective marketing strategies such as social media promotion, content marketing, and influencer collaborations.

9. Provide excellent customer service to build a loyal customer base and generate positive word-of-mouth.

10. Stay abreast of the latest trends and developments in dye sublimation printing to stay ahead of the competition.

.jpg)

Sublimation ink is a special type of ink that is used in dye sublimation printing process when heat pressure is applied it is directly transferred from solid to gaseous state without liquefying. You will receive the set of ink bottles with the package of Epson printers, but these inks are not sublimation inks.

You will need to purchase separate refillable ink cartridges along with dye-sublimation inks. Fedar supplies not only dye sublimation inks, but also DTF pigment ink to meet your needs.

Sublimation Paper:

Just as dye-sublimation ink is different from other inks, the best dye-sublimation paper is different from all other transfer papers. Sublimation paper has a thin layer of polymer to hold the ink, and when heat is applied, the ink becomes part of the fabric by going from solid form to direct gaseous form. Fedar paper is the best paper to use for sublimation. You can choose the paper size according to your machine size and printing needs.

Software Programs:

The last major thing you will need in this process is the use of special software programs.

There is no learning curve to using these programs. Cell phones, PCs can all be used to install them.

Their function is to control the entire sublimation process. They can organize everything automatically without causing any errors. Therefore, people use these software programs to save time.

These software programs include Photoshop, Illustrators, Canvas and many more. Their demand has increased significantly in recent years due to their features and brilliant functions.

Sublimation Printing Process:

Sublimation is a digital printing process for printing on a product made of or coated with polymer or polyester apparel. In the apparel industry, 100% polyester apparel is best suited for sublimation printing.

You first need an image or design to start the sublimation process. You can find these images on the Internet or create them yourself.

The resolution of these designs plays an important role in the quality of the output designs printed on your materials.

Choosing the right images is therefore critical. Their resolution can be set using software programs such as Photoshop for Illustrators.

The second step involves the use of transfer papers. These papers are placed in the heat press with your design on one side. The other side of these transfer papers is lined with watermarks.

These watermarks indicate the side of your transfer paper that cannot be printed through the heat press.

Next, place the printer in a good location. This will prevent you from having to interfere with its functions repeatedly. Then place your image on the transfer paper.

Remember that when you place your image on the transfer, it should always be face down to the heat press.

Your final step is to start the printing process. There is a print button on the control panel of your dye sublimation printer. When you press it, the ink is automatically released and your image is printed onto your material.

Sublimation Printing Benefits:

1. Vibrant and lifelike color quality

Because the dye is absorbed directly into the coated surface at the molecular level, prints exhibit stunningly vibrant colors and photo-realistic detail that bring designs to life. Sublimation offers a much wider color gamut with up to 16 million colors.

2. Long-lasting durability

Once properly heat transferred, sublimation prints essentially become an integral part of the product. This makes them extremely durable prints that will not fade, crack, peel or deteriorate even after years of handling and washing.

Sublimation Printing vs. Heat Transfer

While dye sublimation and heat transfer use heat to transfer designs onto substrates, they are not exactly the same process. Here's a comparison of the two:

| Aspect |

Sublimation Printing |

Heat Transfer |

| Process |

Utilizes heat to sublimate inks and transfer them into the substrate |

Involves transferring pre-printed designs from a carrier sheet onto the substrate |

| Color Capabilities |

Offers vibrant, full-color prints with intricate details |

Can produce colorful designs but may have limitations based on the transfer method |

| Suitable Materials |

Primarily suitable for synthetic fabrics or materials with polyester coatings |

Versatile, and suitable for a wide range of materials including textiles, ceramics, and metals |

| Surface Compatibility |

Requires a smooth and flat surface for optimal image transfer |

Flexible in adapting to various surface textures and shapes |

| Equipment Requirement |

Specific sublimation printers, inks, and heat presses |

Utilizes heat press or other transfer equipment, depending on the transfer method |

| Durability |

Provides long-lasting, wash-resistant prints |

Can achieve durable prints with proper application and material selection |

With vibrant color quality, long-lasting durability, and endless creative possibilities, dye sublimation printing offers an exciting opportunity for entrepreneurs and businesses alike. Partnering with reliable suppliers like Fedar ensures access to the best equipment, inks and support to help you achieve your dye sublimation printing goals.

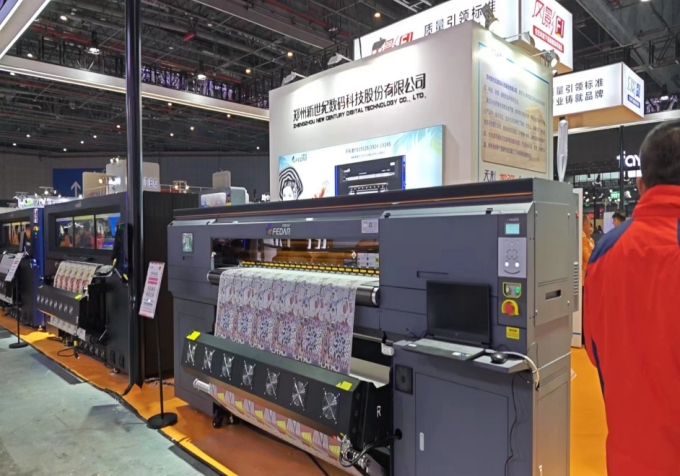

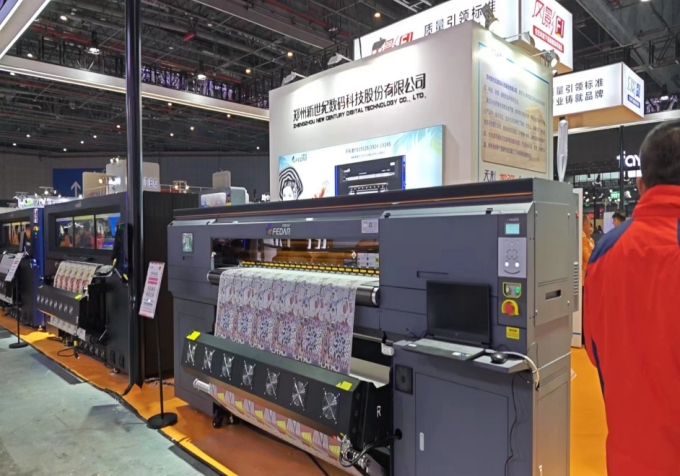

Our company has over

30 models of printers with independent intellectual property rights and patents. Marketed under the esteemed brands of

Skycolor,

Stormjet, and

Fedar brands, these printers cover a wide range, including digital textile printers, UV printers, eco-solvent printers and more. Known for their exceptional quality and performance, these products enjoy an outstanding reputation in the global inkjet industry.

Zhengzhou New Century Digital Technology Co., Ltd. continues to redefine the standards of excellence in wide-format printing technology and is poised to lead the industry in the future.

Feel free to email us at

info@fedar.net to start some great collaborations! Or if you prefer, you can reach us on WhatsApp at

+86 19137185989 for further discussions. Let's make some magic together!

.jpg)

.jpg)

.jpg)